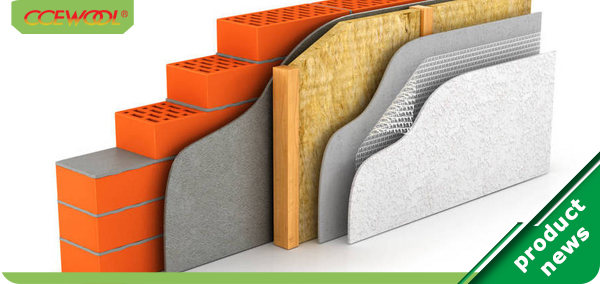

In the construction of stone wool board for external wall, many materials are used. How to judge the adaptability of thermal insulation materials to the project? From the technical point of view, the following aspects are mainly considered:

(1) Properties of stone wool board for external wall:

The lower the thermal conductivity, the thinner the design thickness, the lower the cost and the less the joint design. The thermal conductivity is too large, the required thickness is large, the possibility of forming products is low, and the cost is relatively increased.

(2) Stability of stone wool board for external wall:

Outer wall stone wool board material should have good stability. If it is easy to warp and deform on the engineering board, it is easy to cause the outer surface cracking and water seepage. For example, stone wool board, extruded polystyrene board, phenolic board, polyurethane board, etc., the purchased board must reach a reasonable aging period, so as to largely avoid the problem of cracking and falling off due to the deformation of the board. Degree.

(3) Water absorption performance of stone wool board for external wall maintenance:

When the outer wall thermal insulation material absorbs water, the thermal insulation performance will be greatly reduced. Therefore, the water absorption of the insulating materials used in the project should be low. Today's stone wool board, phenolic board and traditional thermal insulation mortar are all high absorbent materials. The actual thermal insulation performance is far from the theoretical value.

(4) Quality reliability of stone wool board for external wall:

The common insulation board needs to be nailed to the wall, with joints and seams, cold and hot bridges, and the UN spliced joints will affect the insulation effect; for example, the vacuum insulation board may have high insulation performance due to the leakage of sheet materials. Because of the uneven distribution of workers on site, it is difficult to guarantee the quality of traditional inorganic thermal insulation mortar and polystyrene particle thermal insulation mortar. Foamed cement board and inorganic insulating board are easy to crack on site, and the product quality is uncontrollable.

(5) The construction of outer wall stone wool board maintenance materials is convenient:

As a common insulation system, thin plastering system is relatively mature, and many new materials have no corresponding construction convenience. For example, vacuum insulation panels, foam cement boards and other boards are hard to cut on the spot, specifying dimensions. Factory processing and customization, the flatness of the bottom wall is relatively high.

Zibo Double Egrets Thermal Insulation Material Sales Co., Ltd. was Zibo Double Egrets Thermal Insulation Material Sales Co., Ltd.established in 1999, and the branch, CCEWOOL Thermomax Inc., was set up in Canada in 2016.

CCEWOOL Thermomax Inc. T: +(1)7047402348 E: rockwool@ccewool.com Add: 15720 Brixham Hill Avenue, Floor 3, Charlotte, N.C. 28277

Tel:+86-533-7986860 Fax:+86-533-6077229 service@ccewool.com

Zibo Double Egret Thermal Insulation Co.,Ltd Add: Minying Industrial Park Development Zone Zibo Shandong China,255000

SitemapCopyright ©CCEWOOL. All rights reserved.CNZZTechnical Support:NSW

Tel